-cutting-material.jpg)

OUR PRODUCTS PCD

Tools with Poly-Crystalline Diamond (PCD) cutting material can reduce your tooling cost. PCD is the hardest natural mineral, known for its superb hardness and high wear resistance.

We manufacture PCD Tools with advanced processing machine and control the product quality from the very beginning, which leads to PCD tools with high accuracy and good quality with consistency.

PCD (Poly-Crystalline Diamond) ALL PRODUCTS

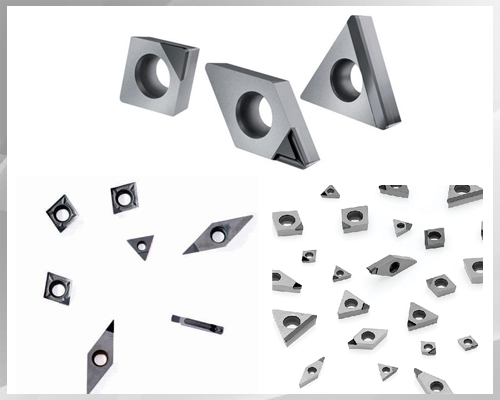

PCD INSERTS

PCD means Polycrystalline Diamond, PCD is used as cutting tools for machining of non ferrous materials like aluminum or copper alloys. Main application of this tools are Stone processing: Diamond circular saw blades, diamond gang saws, diamond band saws are used to saw marble, granite and other stone blocks. Also use in the oil and natural gas industries and the mining industry

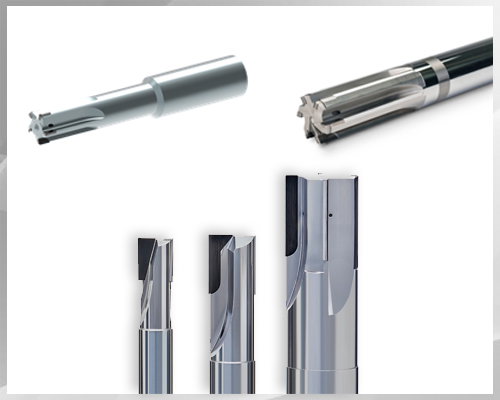

PCD DRILLS

PCD drills from ARROW TOOLS, increase part quality with over all consistency, improved surface finish and less tool changes, resulting in an extended tool life. PCD has good fracture toughness and good thermal stability and is used in making geological drill bits. PCD has the advantages of diamond's high wear resistance with carbide's good toughness.

PCD END MILL

The PCD end mill is the most productive tool on the market today. It stays in optimal conditions for long tool life. It can be used for cutting non-ferrous metals and non-metallic materials such as Carbon Fiber Reinforced Plastic (CFRP), Glass Fiber Reinforced Plastic (GFRP), Copper, Brass or Graphite.

PCD REAMERS

Having standardized the PCD reamer range, ARROW TOOLS is able to supply users with high-performance tools in a very short space of time. All brazed blanks are kept in stock and are finish-ground to the hole dimensions, tolerances and first-cut geometries defined by the user in their order.

DIAMOND CUTTING TOOLS

Mono Diamond : POSALUX TOOLS : FOR JWELLERY PRODUCT (NATURAL DIAMOND AND SYNTHETIC DIAMOND)

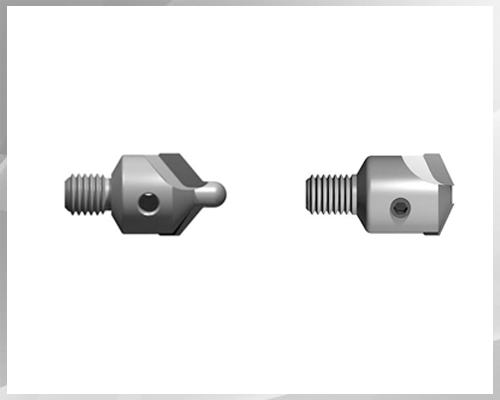

COUNTERSINK CUTTERS / CUTTERS FOR CFRP

For the aerospace industry Arrow Tools Pvt. Ltd. offers a range of cutting edge products such as milling cutters on the countersink and finish operations. These tools stand out for their optimal cutting yield in addition by using them you prevent product edge delamination and achieve shorter machining time and longer tool life without costly rework. Arrow tools Pvt. Ltd. manufactures PCD countersink for composite material and carbon fiber reinforcement plastic (CFRP). High quality PCD provides a superior surface finishing of composite materials requiring minimal effort from the operator. The superiors PCD characteristics ensure the extended tool life of these cutters.