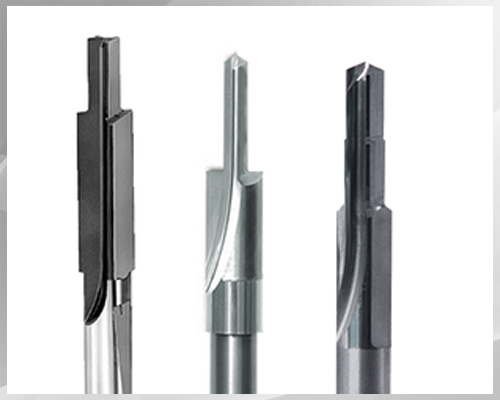

OUR PRODUCTS Solid Carbide Tools

Our knowledge of various carbide step tools allows us to manufacture solid carbide step drills and high speed steel drill that are right for the job. We are the area's foremost leader in creating specialized solid carbide & HSS step drills for all types of applications. Whether the customer supplies us with a CAD drawing or hand sketch, we will help manufacture what they need with the utmost accuracy.

Let Arrow Tools create the perfect through coolant or solid carbide tool that you need to get the job done right.

Solid Carbide Tools ALL PRODUCTS

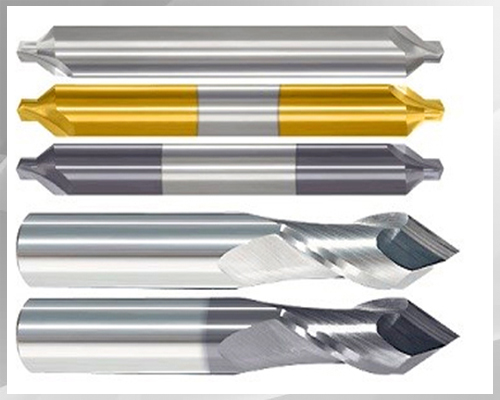

CENTER DRILLS

The centre drill is specially designed for the complicated industrial purpose. These drills are provided with two-sided drill mouth that makes it longer lasting. Both the sides are provided with different diameters that enable the two different drill sizes from a single drill.

COUNTER BORE AND SINK CUTTER

A counterbore is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. The counter bore is an end cutting tool which may utilize a pilot to align the enlarged hole being machined with the preformed hole. Whereas a counterbore is a flat-bottomed enlargement of a smaller coaxial hole, a countersink is a conical enlargement of such. A spotface often takes the form of a very shallow counterbore.

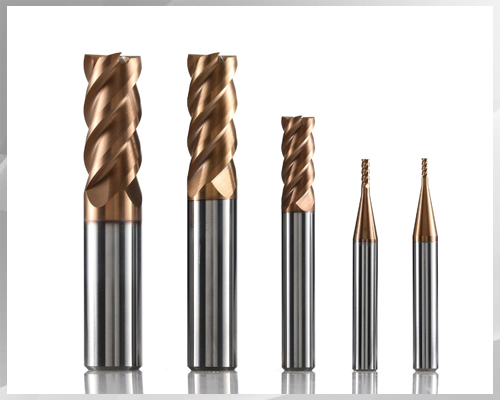

END MILL AND BALL NOSE

End mills (middle row in the image) are those tools which have cutting teeth at one end, as well as on the sides. The words end mills are generally used to refer to flat-bottomed cutters, but also include rounded cutters (referred to as ball nosed) and radiused cutters (referred to as ball nose, or torus). They are usually made from high-speed steel or Solid carbide and have one or more flutes. They are the most common tool used in a vertical mill.

ROUGHING END MILL

Roughing end mills quickly remove large amounts of material. This kind of end mill utilizes a wavy tooth form cut on the periphery. These wavy teeth form many successive cutting edges producing many small chips, resulting in a relatively rough surface finish. During cutting, multiple teeth are in contact with the work piece reducing chatter and vibration. Rapid stock removal with heavy milling cuts is sometimes called hogging.

BALL NOSE CUTTER

Ball nose cutters or ball end mills are similar to slot drills, but the end of the cutters is hemispherical. They are ideal for machining 3-dimensional contoured shapes in machining centers, for example in moulds and dies. They are sometimes called ball mills in shop-floor slang, despite the fact that term also has another meaning. They are also used to add a radius between perpendicular faces to reduce stress concentrations.

FIR TREE MILLING CUTTER

We manufacture this cutter according to customer applications or special requirements. Maximum process reliability thanks to minimal cutting forces and yet very high material removal (Q/min.) at the same time. Only a small number of special milling tools are required.

SOLID CARBIDE HOLE MILL

Durable in nature, these Hole mills are offered in the market in complete safe form. Best in quality, these mills are presented to consumers in complete safe form. Thick in frame, these mills are made of anti-corrosive material. Besides this, we charge minimal cost for this hole mill. We manufacture solid carbide hole mills as per customer drawings.

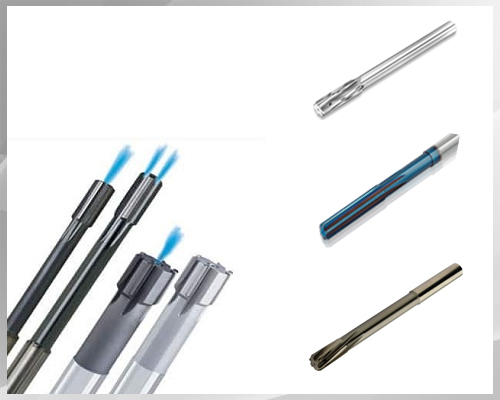

SOLID CARBIDE REAMER

We produce wide range of solid carbide reamers for all materials. Reamers are available with straight and helical flute and a 45° lead cutting angle. Reamer tolerances is H7, it gives high precision and accurate diameter.

Reamers are round cutting tools that enlarge the size of an existing hole, offering high quality of finish and straightness upon completion of the operation. Arrow Tools Pvt. Ltd. has led the industry with its pioneering programs offering service on carbide reamers to customer specifications.

THREAD MILL

Thread milling is a versatile, cost-effective process for anyone cutting a variety of threads, parts and workpiece materials on the same machine. A broad range of materials and hole diameters can also be thread milled with the same tool.

WOODRUFF CUTTER

With a thorough knowledge of the industry, we are engaged in manufacturing, supplying and trading Woodruff Cutter. These cutters are designed and manufactured by the professionals employing quality raw material, which we procure from esteemed vendors of the market. Before the final dispatch, a group of quality controllers rigorously inspects the functionality of these cutters on varied industry laid grounds.

DOVETAIL CUTTER

A dovetail cutter is an end mill whose form leaves behind a dovetail slot, such as often forms the ways of a machine tool. As the number of cutting edges increases, your feed rate should increase to prevent burning and premature tool dulling. More flutes reduce chip load and improve surface finish if feed rate remains the same. The most common flute numbers for general milling operations are two (better space for chip ejection) and four (better surface finish).

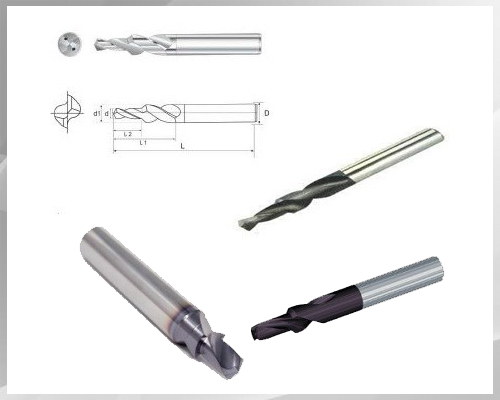

STEPS DRILL

The step drill bit drills holes by rotating in a clockwise direction, through metal sheets of up to a ¼ inch thick. Each step in the drill enlarges the original hole. The smallest bits are self-starting in that they need no pilot drill to start off the hole.

SOLID CARBIDE BURNISHING DRILLS

The burnishing drill has four margins which stabilize it as it is drilling.

The two extra "Burnishing" margins also help to smooth the hole after the "Cutting" margin has cut, giving the hole a better finish than a conventional drill. They also help to make a hole that is consistent from one to another, because the burnishing margin actually moves material back, it is essential for the burnishing drill to be first made of carbide, which has the compression strength and then only of the highest quality.

SOLID CARBIDE TOOL APPLICATIONS

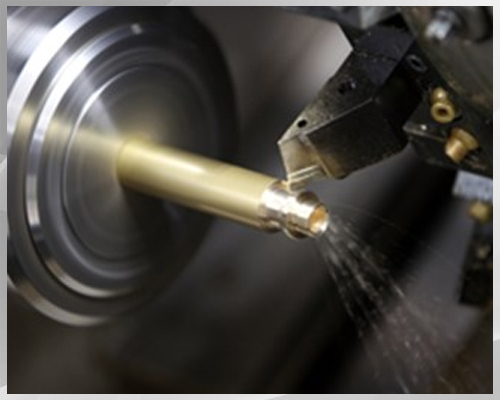

Manufacturing a full range of high performance drills to machine steel, stainless steel, non-ferrous, cast iron and super alloys.These drills are available in L/D ratios 3, 5 and 7 as a standard offering with both solid and through coolant variants. An in-house design workbench is capable of delivering custom solution drills.

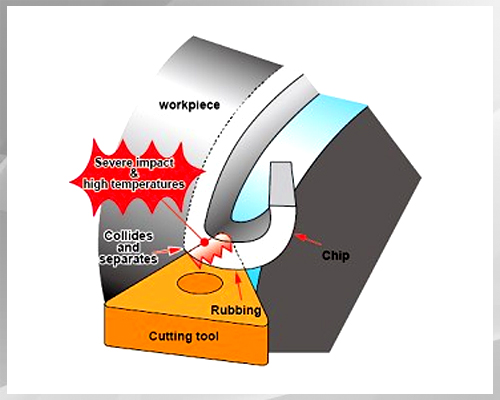

SOLID CARBIDE APPLICATIONS

Carbide cutting surfaces are often used for machining through materials such as carbon steel or stainless steel, and in applications where steel tools would wear quickly, such as high-quantity and high-precision production.